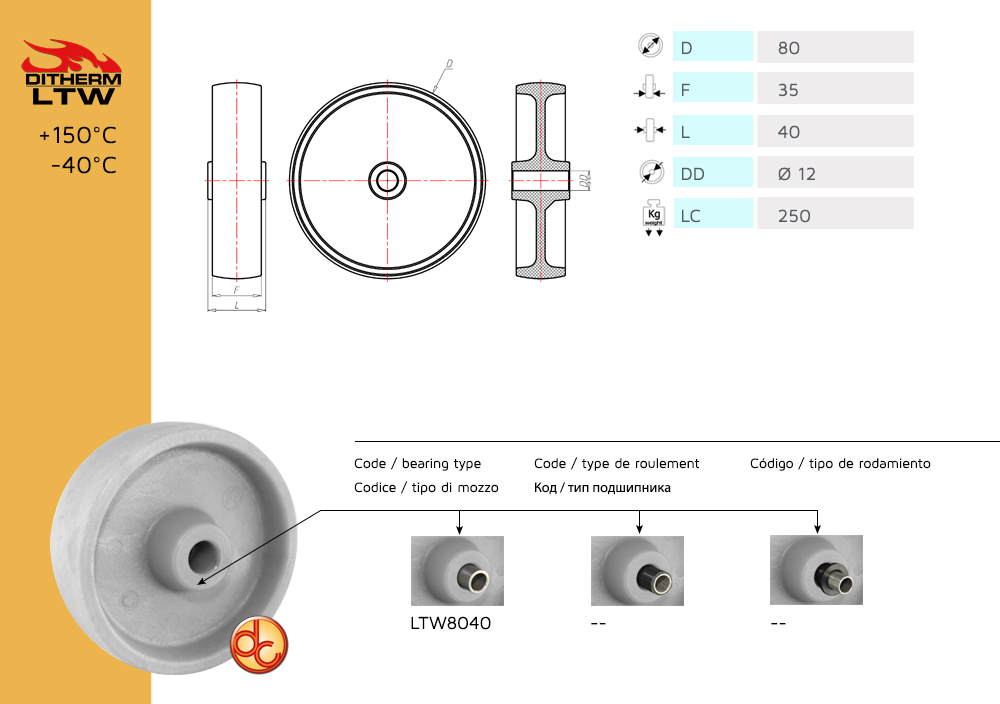

Как правильно подобрать ролик для роклы

Главный фактор это материал изготовления.Сейчас в основном ролики производятся из двух видов материалов.Это полиамид и полиуретан.Ролик из полиамида имеет более прочную структуру,особенно если он изготовлен из качественного материала полиамид 6. Нагрузка тоже очень высокая и может достигать 700 кг на один ролик.Еще одним преимуществом полиамидного ролика является то что его можно использовать при низких температурах,а так же в цехах с агрессивной производственной средой.Единственным несущественным минусом является твердость ролика из полиамида,а соответственно громкий и твердый ход гидравлической тележки.

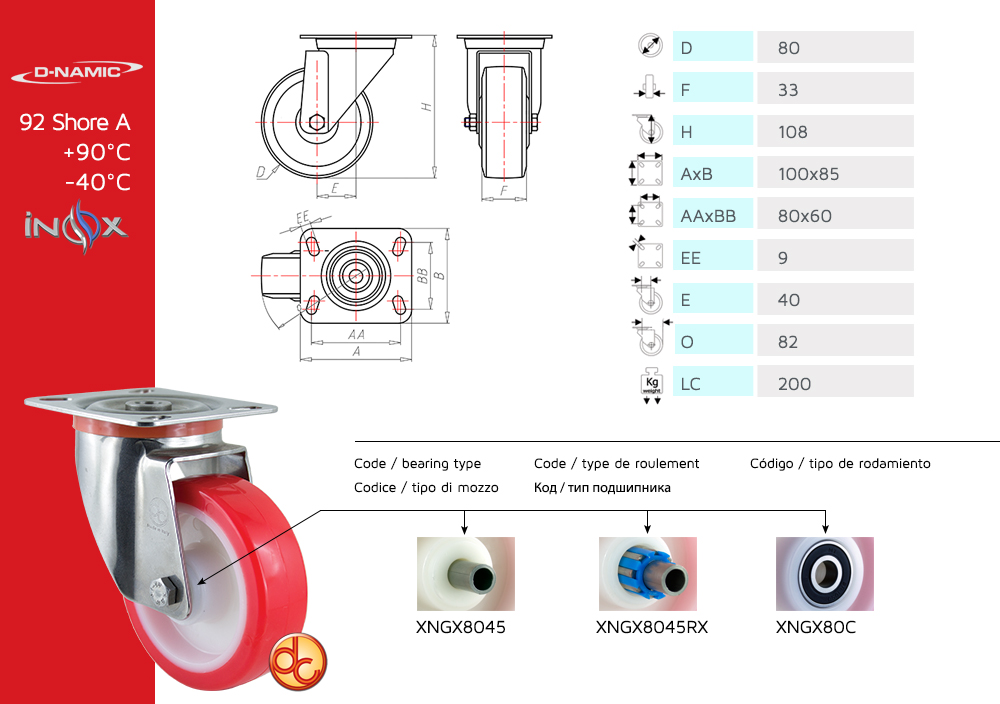

Ролик из полиуретана напротив имеет мягкий ход за счет шины из полиуретана.И в данное время большинство производителей гидравлических тележек комплектуют свои изделия именно этим роликом.

Еще одним важны моментом являются параметры ролика,диаметр и ширина.Здесь есть два основных размера 70х60 и 80х70 мм.

Сегодня рынок Украины перенасыщен предложением различных колес для тачек.В своей основной массе данный вид колес поставляется из Китая. Существует расхожее мнение что китайская продукция не является качественной.Это и правда и не очень.Поэтому при выборе

Сегодня рынок Украины перенасыщен предложением различных колес для тачек.В своей основной массе данный вид колес поставляется из Китая. Существует расхожее мнение что китайская продукция не является качественной.Это и правда и не очень.Поэтому при выборе

В ассортименте предлагаемом СНБ Компани есть большой выбор колес с резиновой шиной.Почему колеса именно с резиновой шиной настолько популярны у покупателей использующих колеса для тележек? На этот вопрос есть несколько несколько ответов.

В ассортименте предлагаемом СНБ Компани есть большой выбор колес с резиновой шиной.Почему колеса именно с резиновой шиной настолько популярны у покупателей использующих колеса для тележек? На этот вопрос есть несколько несколько ответов.

СНБ Компани постоянно работает над расширением ассортимента колес для тележек. До недавнего времени мы поставляли обычные

СНБ Компани постоянно работает над расширением ассортимента колес для тележек. До недавнего времени мы поставляли обычные

Колеса серии 30 SMART являются одной из разновидностей аппаратных колес представленных на рынке Украины.Данная серия отличается широким протектором шины и имеет твердость 85 Shore A. Серия 30 SMART используется при производстве торгового оборудования,а так же на тележках которые используются в гостиницах,офисах,на пищевом производстве,а так же в сфере гостиничного сервиса.

Колеса серии 30 SMART являются одной из разновидностей аппаратных колес представленных на рынке Украины.Данная серия отличается широким протектором шины и имеет твердость 85 Shore A. Серия 30 SMART используется при производстве торгового оборудования,а так же на тележках которые используются в гостиницах,офисах,на пищевом производстве,а так же в сфере гостиничного сервиса.

Колесо для мусорного контейнера наверняка

Колесо для мусорного контейнера наверняка